Introducing Minerva: the innovative all-plastic vial closure system

Content index

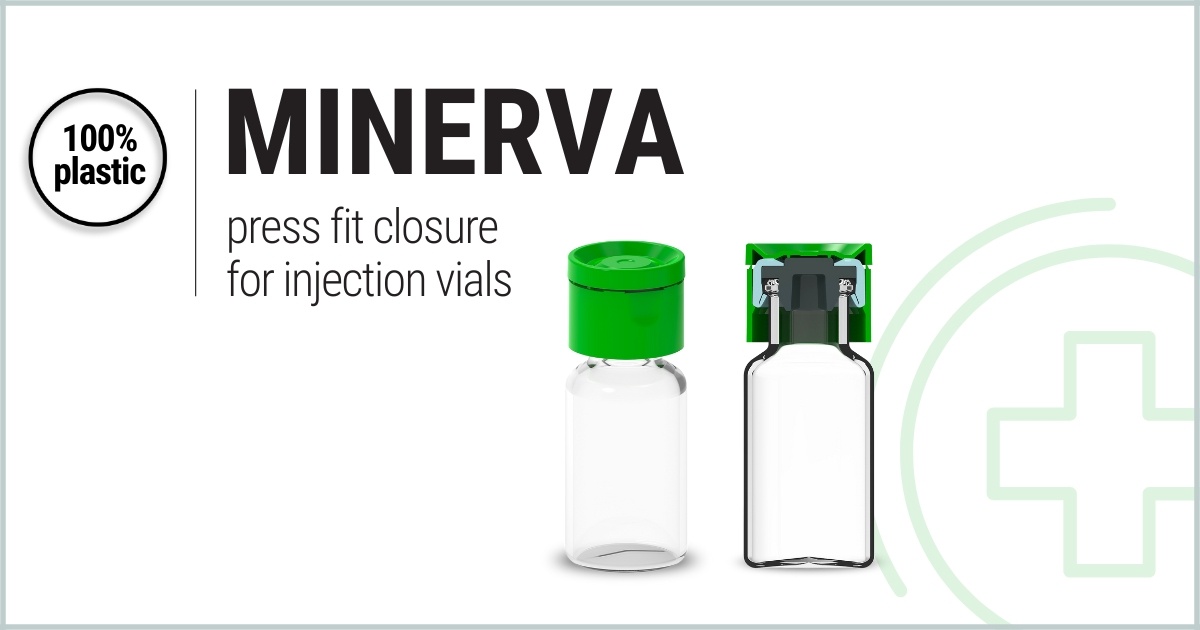

Guala Dispensing Pharma is excited to introduce Minerva, an innovative, all-plastic closure system designed specifically for ready-to-use (RTU) glass vials.

Unveiled for the first time at the CPHI Worldwide fair in Milan, Minerva takes its name from the Roman goddess of medicine, representing a new era of safer and more efficient vial closures. With a design that eliminates the need for traditional aluminum tear bands, Minerva streamlines the filling-line process, delivering improved safety and efficiency.

All-plastic vial closure for enhanced efficiency and safety

One of Minerva's standout features is its unique three components assembly, all made of plastic: stopper, fixture and flip-off cap. The innovative all-plastic construction replaces the aluminum tear band traditionally used in vial closures.

Snap-on closure: precision sealing for nested vials

The Minerva closure employs a snap-on application that ensures a perfect seal with just one step, allowing operators to secure up to one hundred nested vials at once. Designed for compatibility with automatic machines, this efficient sealing solution adheres precisely to the glass, speeding up production time and reducing overall operational complexity. Through a patented design that perfectly matches glass and plastic tolerances, Minerva guarantees both a tight seal and optimal product integrity, guaranteeing increased safety during transport.

Customizable flip-off cap for branding and product differentiation

Branding flexibility is another advantage of the Minerva closure. Its flip-off cap can be manufactured in a variety of colors, allowing pharmaceutical companies to customize packaging for brand recognition and product differentiation. This wide color range helps brands enhance the visual appeal and functionality of their products, providing a clear edge in a competitive market.

"Spring Effect" to optimize injection vial sealing

Our engineers have integrated an innovative spring effect into the Minerva vial closure system, featuring a flexible design that adapts to small dimensional variations in glass injection vials without generating excessive pressure. This is particularly valuable when vials are arranged in nesting, where dimensional tolerances are inevitable, and during the capping process, where excessive force could cause glass breakage or closure deformation. The spring effect reduces waste, enhances production efficiency, and ensures optimal and secure sealing, which is crucial in the pharmaceutical industry.

Tamper-evident features for enhanced vial security

Security is of utmost importance in the pharmaceutical sector, and Minerva is designed with a tamper-evident feature that provides clear indications if the seal has been broken. This security measure protects the integrity of the product, instilling confidence in both healthcare providers and end-users that the contents remain safe and unaltered.

Versatile sterilization and high-quality manufacturing

Guala Dispensing Pharma manufactures Minerva in its ISO 5-certified facility, ensuring a controlled, high-quality production environment. The closure is ready for several sterilization methods, including gamma, steam, and ethylene oxide (ETO), enabling broad compatibility with current sterilization practices. Material research ensures the closure's resistance to extreme conditions, withstanding temperatures from -40°C to 120°C.

Compatibility with the pharmaceutical industry’s main vial sizes

Minerva has been meticulously engineered to fit the main vial sizes used in the pharmaceutical industry, specifically the 13mm and 20mm diameters. While it requires a specific neck design on the glass vials, this adaptability ensures it meets the needs of today’s pharmaceutical processes and offers an optimized solution for the vast majority of all the standard transfer devices and vial adapters.

Optimal solution for a range of vial applications

Minerva is suitable for a broad spectrum of vial applications, from established pharmaceuticals to emerging molecules, as well as varying batch sizes and laboratory trials. Its compatibility with the industry’s main transfer devices further extends its usability, making it a versatile choice for pharmaceutical companies seeking both innovation and operational efficiency.

Guala Dispensing Pharma sets a new standard in pharmaceutical vial closures

With this new product, Guala Dispensing Pharma - a company within the multinational Guala Group and previously known as Bisio Progetti - expands its range of packaging solutions specifically tailored to meet the demands of the pharmaceutical and nutraceutical industries. Combining an all-plastic design with enhanced safety, efficiency, and customization, Minerva is an ideal choice for companies focused on innovation and reliability.

If you’re looking to securely package your pharmaceutical products with our innovative Minerva closures, click here and contact us to learn more.